You’ve been tasked with the job of selecting industrial magnetic separators. What are some things to consider?

Depending on where the magnetic separators will be used, there are several questions to ask yourself. Ideally, you want to make sure the products you buy end up solving your current issue(s) on an ongoing basis. Will the magnet be something that’s easy to use and easy to clean? Will it help reduce OSHA risks? Will it be of sufficient strength and coverage to do the job it needs to do? These are key questions. committed

Durability and Longevity

Basically, you want magnetic separators that are both efficient and effective when it comes to foreign metal control. After all, you’re trying to reduce risk. And, furthermore, you hope that the product you buy lasts a long time without demagnetizing, right?

Sanitary Options

Look for magnetic separators which are designed and built to be sanitary as well as sized to meet your product and process lines. Ideally, go with well-known and respected brands that meet best practice manufacturing standards.

How IPES Can Help

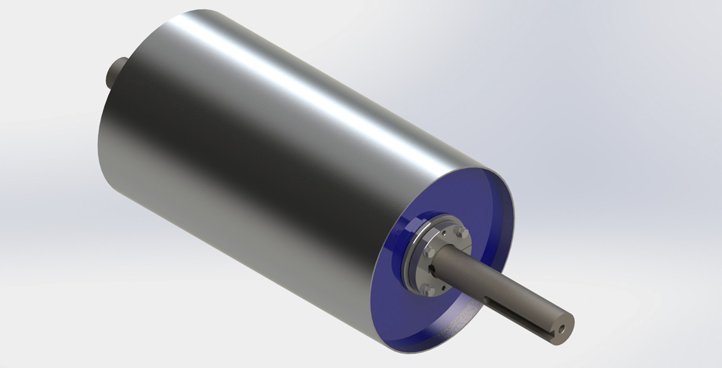

IPES sells industrial strength magnetic sweepers and magnetic separators for all industries. We can help you figure out what to get when you tell us the material you’re separating, the temperature of your workspace, and the flow rate.

All of these factors matter when choosing the most effective industrial magnetic separator for the job at hand. Let us know if you need to separate dry, free-flowing granular product, dry product with some bridging tendency, or liquid/slurry products. Also, keep in mind that magnetic separators work best when the contamination is presented to the surface of the separator so you’d want a configuration that provides a thin burden depth over or under the magnet in order to capture the ferrous contamination.

Please call IPES and tell us about your specific needs. Our number is 877-781-4660. You can also email us at info@ipesmag.com. Check out some of our products here.