Permanent Drum Magnets

Made With Ceramic 8A and Rare Earth Magnet Material

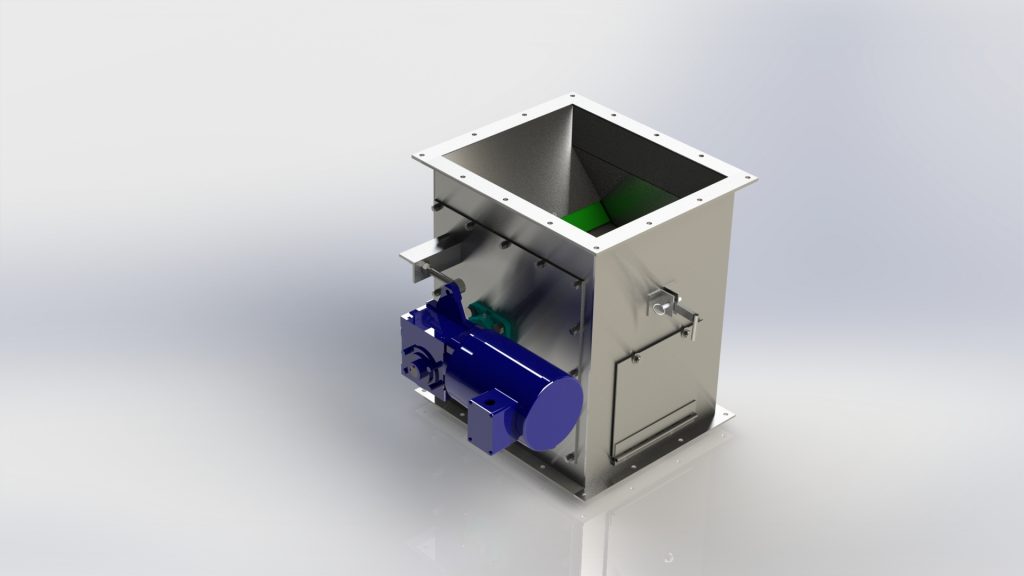

Magnetic drum separators efficiently and completely separate iron-based material from dry, bulk products. Using a free-flowing processing system, plastic, non-magnetic metals and other materials move through a stainless-steel permanent drum magnet while the magnetic separator consolidates any residual iron-based metals. The metals adhere to the high-powered magnetic drum while the rest of the pure materials move past the drum to the crushing, stamping, sorting or other processes.

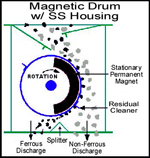

How Magnetic Drums Separate Ferrous Metal

They are comprised of a stationary permanent magnet, either standard Ceramic-8A or Ferrite magnets enclosed in a non-magnetic stainless-steel drum. Product flow is diverted so that it falls onto the top and flows across the surface of the drum. Ferrous matter contained in the product flow is drawn to the drum’s surface (and held against it) by the powerful magnet housed inside.

While non-ferrous products falls from the side of the drum in a normal manner, ferrous metal clings to its surface. As the portion of the drum with the ferrous material rotates to the side opposite the product flow, the magnetic field is reduced so that the ferrous matter falls from the drum into a collection container. The end result is purified product ready for processing without the worry of costly damage caused by tramp metal.

Tell Us About Your Operation and Magnetic Drum Needs

Use the application data sheets below to specify the requirements for your magnetic drum separator. We’ll design the appropriate style, size and magnetic strength for your drum separator using your specifications.

Magnetic Drum Application Data Sheets:

Industry Applications for Magnetic Drums:

- Food Processing Industry

- Pharmaceutical Industry

- Chemical Processing

- Tire and Rubber Recycling

- Shot Recovery

- Minerals Processing

- …and many more

Get A Quote For Your Application

Fill out our Application Data Sheet Above or Call Us At (877) 781-4660